|

WOOD/EPOXY

BOATBUILDING

NEWS & BOAT BUILDING

TECHNIQUES:

Hi fellow boat builder, this is the start

of our on line - BOAT BUILDING NEWS

-

which will

be updated on a regular basis. We can only share with you a fraction of the information

included in our BOATBUILDING E-BOOKS. You can

email us regarding specific boatbuilding questions and we will be pleased to give you a

prompt reply. In the meantime ...good boat building ....from us all at Bruce Roberts.

Suggestion! Let this and other pages of this site DOWNLOAD or on USB memory

stick into your hard disk and view at leisure. Please email me your comments on our

site....criticisms as well as other comments please.

MOLDED PLYWOOD

OR VENEER

This method of construction can be used to build several of our designs,

and boat plans are available based on this technique. From full size patterns supplied with the

boat plans , station frames are marked and cut out of scrap timber and plywood. Stringer

positions are marked and notched. The frames are erected on a prepared strongback and the

stringers, keelson and stem are added. Very little fairing off is necessary as the

stringers go in at the correct angle and allow the plywood or veneer strips to be added

glued and nailed to the stringers.

The plywood or veneer strips are applied diagonally and sometimes

vertically and fore and aft as shown in the boat plans. To ensure a good bond between the

layers, staples are used to pressurize the glue while this hardens. If silicon bronze or

stainless steel staples are used they may be left in the hull.

|

|

Waverunner 24 W - SEE MORE

( Planing hull )

WOOD / EPOXY

POWERBOAT plans & FULL

SIZE FRAME PATTERNS

ALL boat plans & Full size patterns come with a BONUS DOWNLOAD or on

USB with FREE a dinghy plan, rigging boat plans, placement of anodes, how to build a sea hood, how to

build fuel & water tanks, engine installation details, electrical

schematic & plumbing details; all included to assist you to build & complete

your boat. |

|

COASTWORKER 28 - 32- 36 - SEE MORE

FISHERMAN WORKBOAT

WOOD EPOXY or ALUMINUM

boat plans & FULL SIZE FRAME PATTERNS

Package Includes

latest building plan updates & revisions, PLUS direct

contact with the designer Bruce Roberts-Goodson

EMAIL BRUCE

ALL boat plans & Full size patterns come with a BONUS DOWNLOAD or on USB

with FREE a dinghy plan, rigging boat plans, placement of anodes, how to build a sea hood, how to

build fuel & water tanks, engine installation details, electrical

schematic & plumbing details; all included to assist you to build & complete

your boat. |

|

Waverunner 342 - SEE

MORE

(SEMI-DISPLACEMENT OR PLANING HULL)

STEEL, ALUMINUM, WOOD / EPOXY or FIBERGLASS BOAT PLANS & FULL SIZE FRAME PATTERNS

|

|

Coaster

TY 28 - 32 - 36 SEE MORE

WOOD EPOXY BOAT PLANS & FULL SIZE FRAME PATTERNS

|

|

COASTWORKER 28 -

32 - 36 -

SEE MORE

FISHERMAN WORKBOAT

WOOD EPOXY or ALUMINUM

BOAT PLANS & FULL SIZE FRAME PATTERNS

Package Includes

latest building plan updates & revisions, PLUS direct

contact with the designer Bruce Roberts-Goodson

EMAIL BRUCE

All BOAT PLANS & Full size patterns come with a BONUS DOWNLOAD or on

USB MEMORY STICK with FREE a dinghy plan, rigging boat plans, placement of anodes, how to build a sea hood, how to

build fuel & water tanks, engine installation details, electrical

schematic & plumbing details; all included to assist you to build & complete

your boat. |

|

WAVERUNNER 44 - SEE MORE (Semi-displacement or Planing)

STEEL, WOOD/ EPOXY

boat plans & FULL SIZE FRAME PATTERNS |

|

NEW |

MEDITERRANEAN 45 - SEE

MORE

WOOD EPOXY

OR FIBERGLASS

boat plans & FULL SIZE FRAME PATTERNS |

![wr45-06[1].jpg (18379 bytes)](images/wr45-06[1].jpg)

![wr45-10[1].gif (19945 bytes)](images/wr45-10[1].gif) |

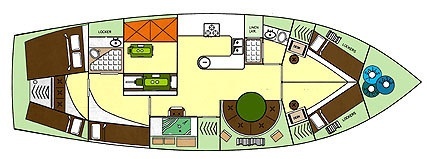

Waverunner

45 SEE MORE Version B (Aft Cabin)

(Semi-displacement or Planing)

WOOD EPOXY

STEEL

or FIBERGLASS

BOAT PLANS & FULL SIZE FRAME PATTERNS

ALL boat plans & Full size patterns come with a BONUS DOWNLOAD or on USB

- YOU CHOOSE DOWNLOAD OR USB

. . .with FREE a dinghy plan, rigging boat plans, placement of anodes, how to build a sea hood, how to

build fuel & water tanks, engine installation details, electrical

schematic & plumbing details; all included to assist you to build & complete

your boat.

Waverunner

45 SEE MORE

Trawler version

WOOD EPOXY

STEEL

or FIBERGLASS

BOAT PLANS & FULL SIZE FRAME PATTERNS |

SEE MORE

|

TRAWLER YACHT 485 WOOD EPOXY

BOAT PLANS & FULL SIZE PATTERNS

ALL boat plans & Full size patterns come with a

BONUS DOWNLOAD or on USB MEMORY STICK -

with FREE a dinghy plan, rigging boat plans, placement of anodes, how to build a sea hood, how to

build fuel & water tanks, engine installation details, electrical

schematic & plumbing details; all included to assist you to build & complete

your boat. |

|

ATLANTIC

550 / 17m SPORT FISHERMAN

WOOD EPOXY BOAT PLANS & FRAME

PATTERNS

|

Similar design shown

SEE MORE |

PASSAGEMAKER TY 585

WOOD EPOXY

COMPLETE boat plans & FULL

SIZE PATTERNS

Plus BONUS boat plans plus FREE

e-BOAT BUILDING BOOK

PLAN PACKAGE includes latest sail

boat plans, sailboat building plan updates & revisions, PLUS direct contact with the

designer Bruce Roberts-Goodson |

|

EURO 2150 Motor Yacht

WOOD EPOXY BOAT PLANS &

PATTERNS |

|

ROBERTS 434

WOOD EPOXY

Hi Bruce,

Here is an update on my boat

construction of your ROBERTS 434. The more I get into this project the more I am

admiring your skills as a navel architect. I just realized that the engine

can be made to easily be pulled up thru the cockpit floor without damaging

the rest of the vessel. Fantastic! When I attended the Chicago boat show

last winter, I did not see that at all on the factory models; in fact the

engine compartment was so compact, I pitied the mechanic that had to work on

it.Have a Spiffy Day! Earl |

|

|

CENTENNIAL SPRAY 38

WOOD / EPOXY

Diagonal veneers added after strip planking is completed. |

|

|

CENTENNIAL SPRAY 38

WOOD / EPOXY

Hull upright ... pattern has been made for ballast keel

& this will be installed at later stage. |

|

Interior framing added as per boat plans. |

Hi Bruce, Just thought we'd update you with the progress of

our CS38. As of today the 30th of May, we're past halfway through planking the first

diagonal layer on the hull. We completed fairing the fore and aft strip planking early

last week. We have a small web page up showing progress (of course it IS about 3 weeks out

of date, but there's a lag in getting film out of the camera!): Regards, Rob

McGill & Nina Morissette

See complete

list of Sail & Powerboat plans for building in wood |

|

|

“BOUNDER”

Ketch Rigged SPRAY 45 Wood /Epoxy

LENGTH:

Overall 52’…On deck 46’ BEAM 20’-0

DRAUGHT Cruise 5’6” DISPL:

Empty 20 tons Loaded 22 tons.

CONSTRUCTION:

West System, using double strip plank and epoxy resin,

and

covered with a heavy epoxy/fiberglass skin. Outside ballast keel of five tons |

|

|

SPRAY 45 Wood /Epoxy

NEW

VERSION 'B'

boat plans and patterns available

for wood/epoxy

construction

MORE INFO CS45

MORE INFO CS38

MORE INFO CS36

MORE INFO CS34 |

|

![r470-04[1].gif (9835 bytes)](images/r470-04[1].gif)

|

ROBERTS 470

WOOD EPOXY

This Wood/Epoxy sailboat was built in Turkey

and is currently operating as a charter boat in that area. The operation has been

sufficiently successful to enable a second vessel to be ordered from the same builders.

Study boat plans Available

MORE INFO Roberts 470

|

|

|

ROBERTS 532

This molded veneer Wood/Epoxy hull was built in

Brazil where good timber is still relatively plentiful. Many Bruce Roberts designs are

available for use where this method of construction can be used.

MORE INFO

BUILDING TIP: When installing veneers or

other material that requires temporary staples, one of the most onerous jobs is removing

the staples. Many methods have been tried but this one successfully used by Russ Stevenson

works well....buy some narrow THIN packaging METAL tape and this can be used underneath

the staples....easy to remove when the glue has set...simply give a hefty tug on one end

of the tape and the staples come out without a whimper...make sure to wear goggles as

staples may fly in all directions.

|

|

|

SPRAY 28

This boat is being built by Phoenician Yachts

This and several other Spray designs can be built in sheet plywood as well as

the many CENTENNIAL Spray strip plank versions.

See complete list of

Sail & Powerboat plans for building in wood |

Dan

Aadland:

Building of his Spray 27 in Wood Epoxy

The lifelong desire to sail has prompted my present (major) project, a

Spray 27 cutter designed by Bruce Roberts. This is the second smallest of his Spray series

and the larger of the two trailerable ones. A multi-chine plywood design, the cutter can

be built with either marconi or gaff rigs and in either pilot house or conventional

sailboat configuration. Luckily, decisions on those two matters need not be made until

bulkheads are installed, so I have a while yet to decide.

I made two modifications. First, the Sprays have a conventional transom which turns to

vertical for the upper one foot. I kept the taper of the transom all the way aft, which

will increase cockpit (or lazarette) space and overall length (to about 28'). The shape is

more pleasing to my eye. Secondly, I am building the hull with a modified stitch-and-glue

or, more accurately, epoxy chine method. I’ve built the hull over the same temporary

frames specified but eliminating the chine logs and instead edge-gluing the plywood panels

with filled epoxy. The hull is roughed in and when fibreglasses will be turned over with

the temporary frames still supporting it. At that point the fillets of filled epoxy will

be installed inside as the chines. This modification was done with the blessings of Mr.

Roberts himself, incidentally.

A Spring ‘99 Update: I completed the planking, built up the keel with fir, and built

a steel ballast box to be later filled with lead and thickened resin. This ballast

box, still empty, was fitted into place and the wooden keel laminated up around it.

Then I removed it to be bolted in position later with the hull upright. I also

located an old-but-good Yanmar 8h.p. diesel, the old horizontal cylinder model, and

purchased it for later installation.

A stern view of the hull, now covered with 6 oz. fiberglass cloth set in epoxy

resin. (Much sanding and fairing remains before it will be ready for paint.)

To turn the hull we had, naturally, a party. Two heavy Polly ropes were run from the

ends of the trusses on each side of our pole shed, under the hull (but over the building

form), then to cable-type “come-along's.” To protect the hull we padded

the area with tires and also put foam pipe insulation over the ropes. Then we

cranked on the come-alongs until the hull lifted off the form. We lifted the hull until it

went over gently onto the ropes. Then everyone quickly skidded the building form

forward out of the way. Then we pushed the hull back onto the concrete building

platform and blocked it.

Final positioning of the hull was easy, and with this nice old-fashioned straight

keel design, the hull ended up dead level with the waterline (as shown by the marks on the

temporary frames still inside). Emily and I posed in front of our sailboat to be,

then she posed me by the stern. We’re tentatively planing to name the boat Sjo

Hest, “sea horse” in Norwegian, a marriage of our Scandinavian heritage and our

preoccupation with the world of horses. Hopefully it will take us over the waters of

Puget Sound and the Sea of Cortez. Watch this space for more on the

building of Dan Aadland's Spray 27

MORE INFO Spray 27 |

![s27-08[1].jpg (9077 bytes)](images/s27-08[1].jpg)

Setting up the frames |

![s27-10[1].jpg (22987 bytes)](images/s27-10[1].jpg)

Here the ballast keel section is being welded |

![s27-09[1].jpg (10867 bytes)](images/s27-09[1].jpg)

Ballast keel in position, then being removed after completing lamination of

the wooden sections. |

![s27-11[1].jpg (9431 bytes)](images/s27-11[1].jpg)

Hull ready for turn-over |

![s27-12[1].jpg (8703 bytes)](images/s27-12[1].jpg)

Dan and Emily Aadland |

CLICK BELOW TO GO TO:

SAILBOAT DESIGNS POWERBOAT DESIGNS INDEX

PAGE |